Block Posting, an overview...

Many thanks go out to Larry at Endyn for his guidance through this

process. No technical details are exposed in this set of pictures.

If you need that info, work it with Larry.

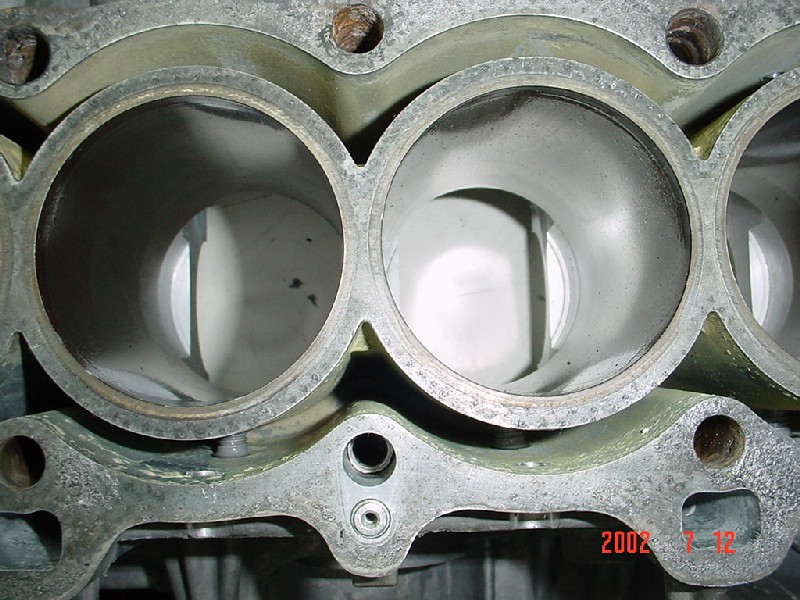

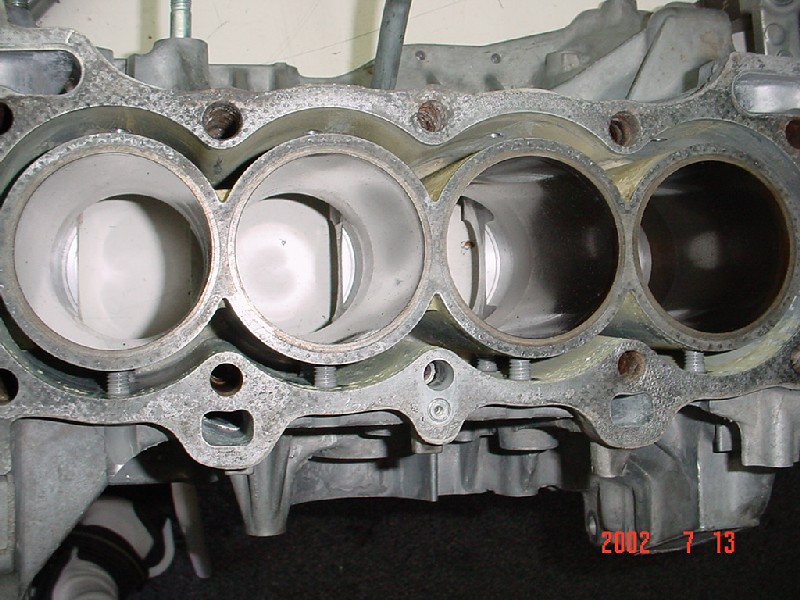

Block "posting" is a method of reinforcing an open deck block to

make the sleeves less susceptible to cracking/breaking due to stress

caused by high RPM and/or high cylinder pressures (boost). A common

method of reinforcing cylinders is by the use of a blockguard. When

properly installed, a blockguard has proven successful for many people.

The key word there is properly. Most good blockguards are machined

to fit your block, welded in, and then a bore/hone job is required to true

everything back up. Additionally, the "good" blockguards have generous

room for cooling. The "hammer it in" style blockguard has been the culprit

in many blockguard related horror stories. Do it right, or don't do it all!

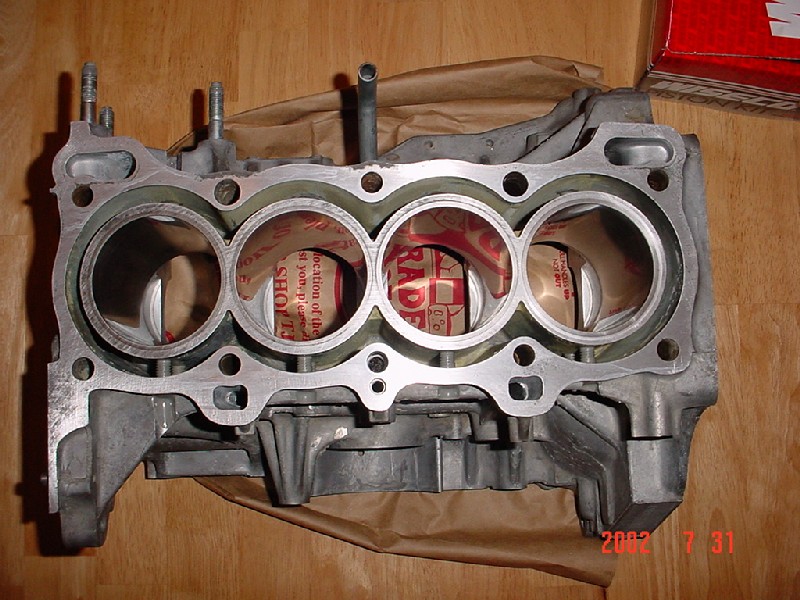

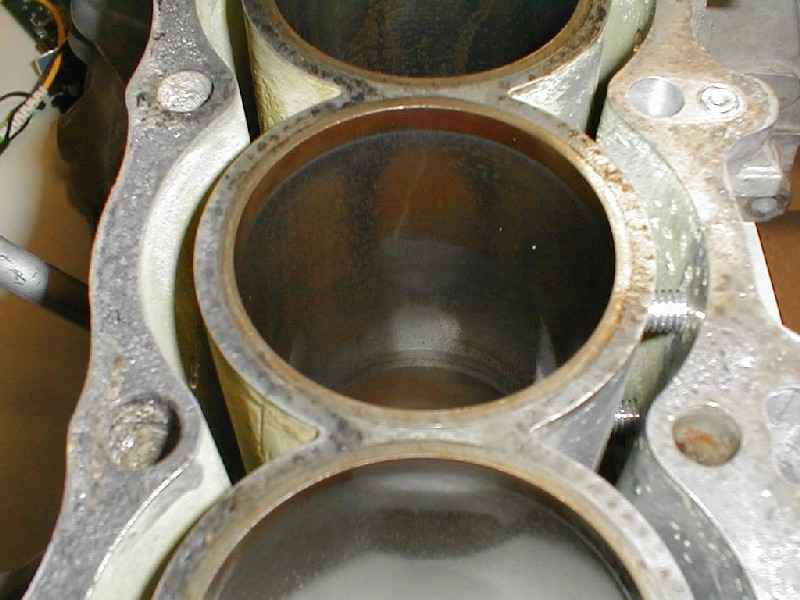

Your typical blockguard reinforces the cylinders only at the top of the

deck and it looks like this:

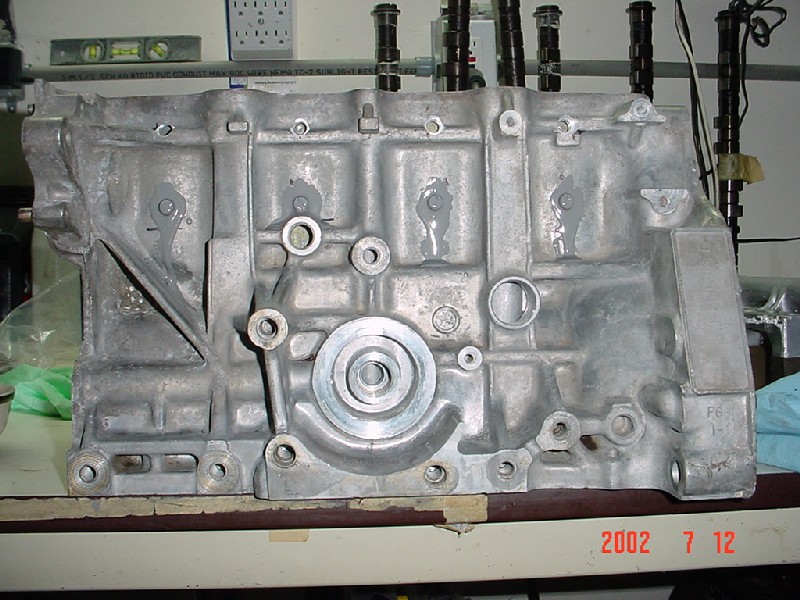

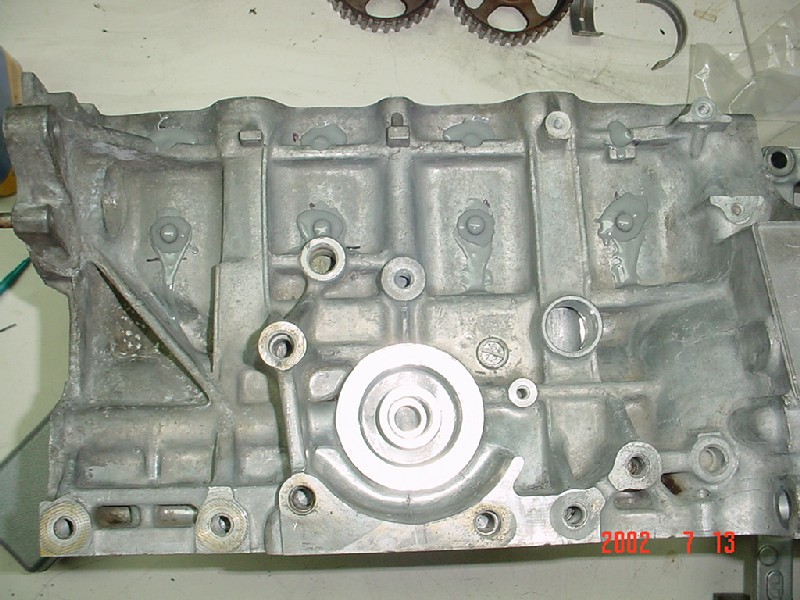

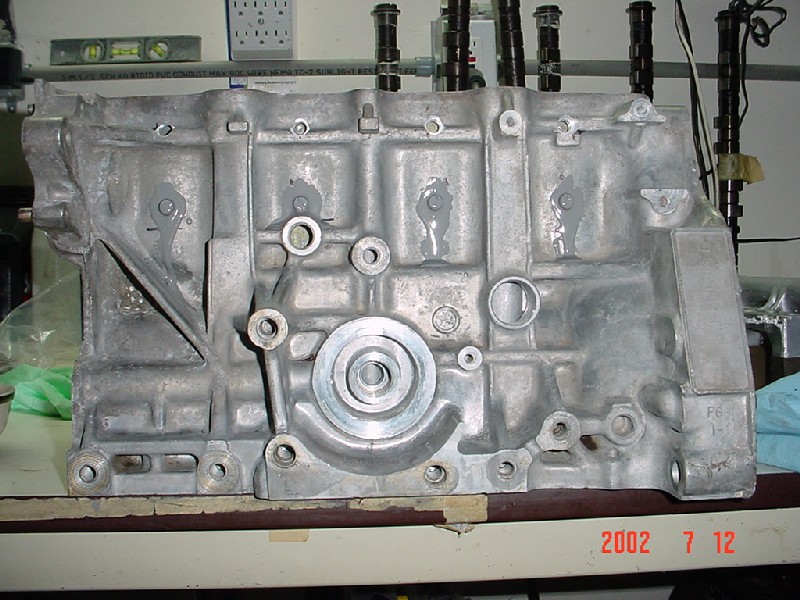

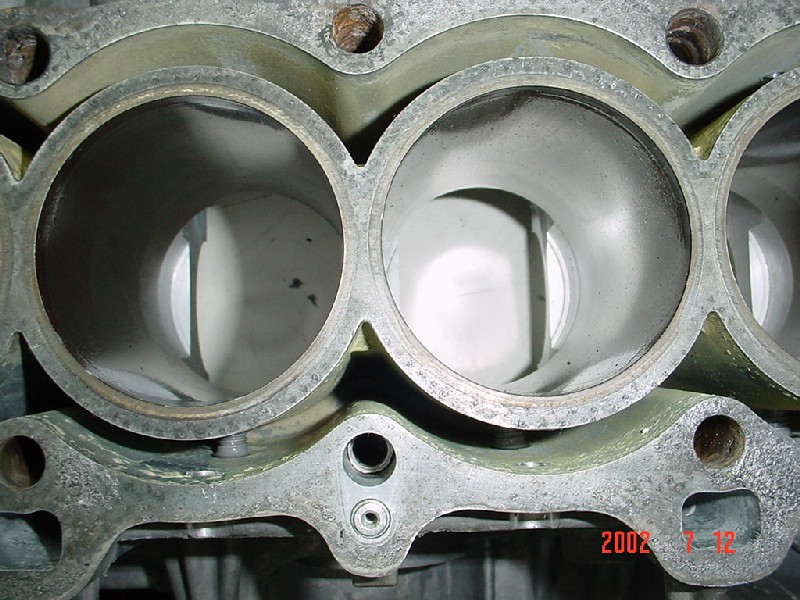

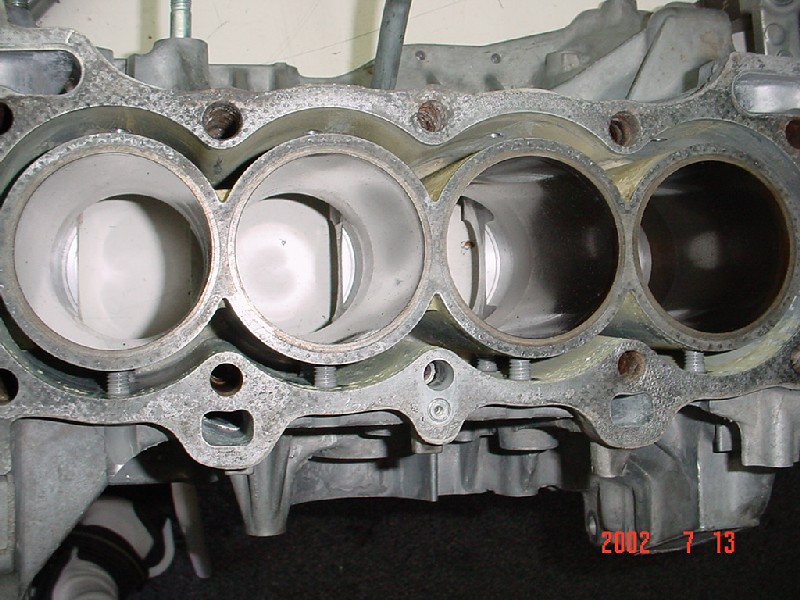

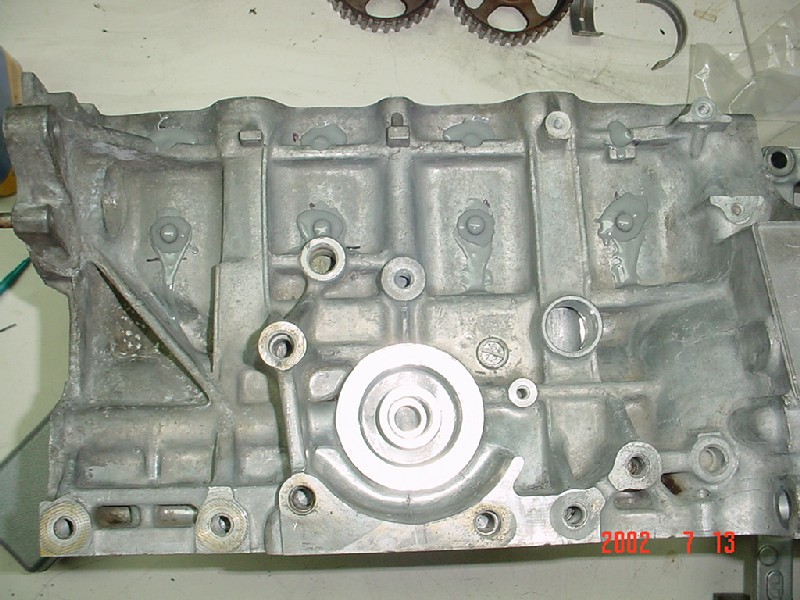

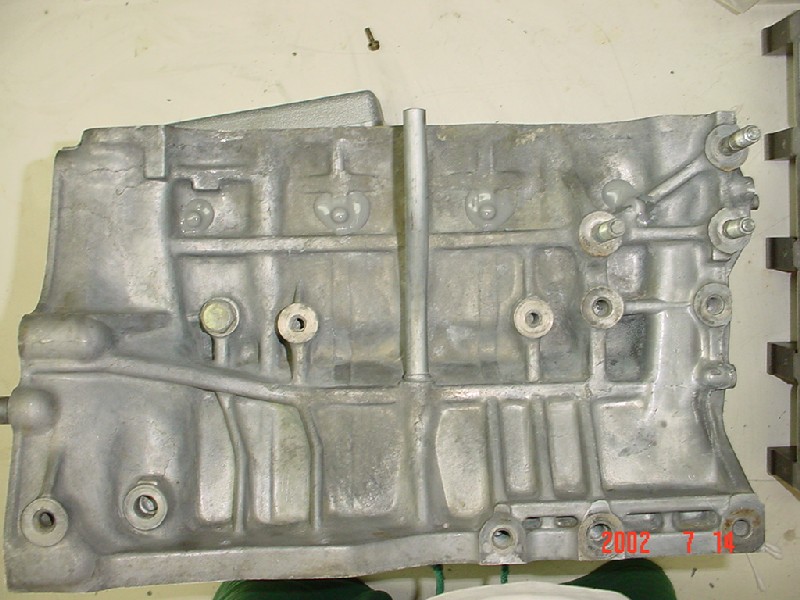

Posting reinforces the cylinder at 12 strategic points where side load

is very high. For the garage mechanic, this method is actually easier

(IMO) and will significantly increase the strength of an open deck block. 12

aluminum threaded posts are screwed into the block to reinforce the sleeves

where they need it the most.

Ok, now the pics:

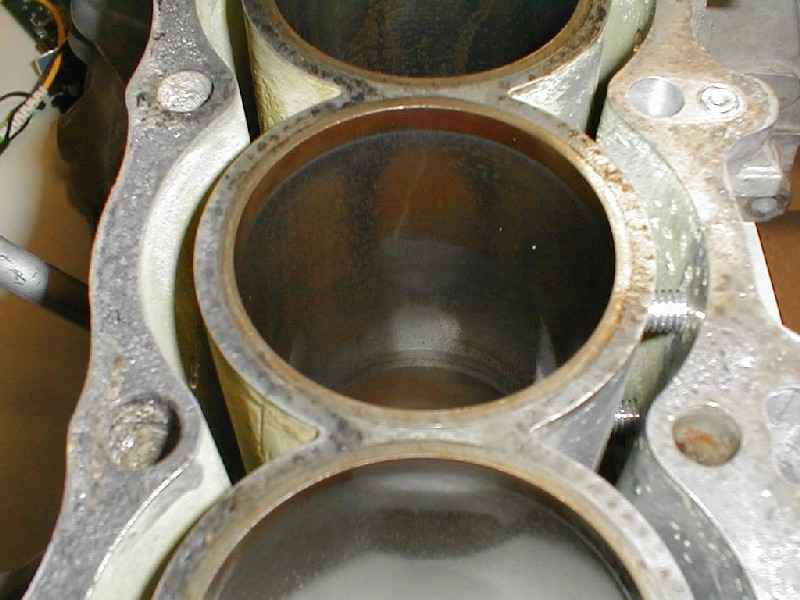

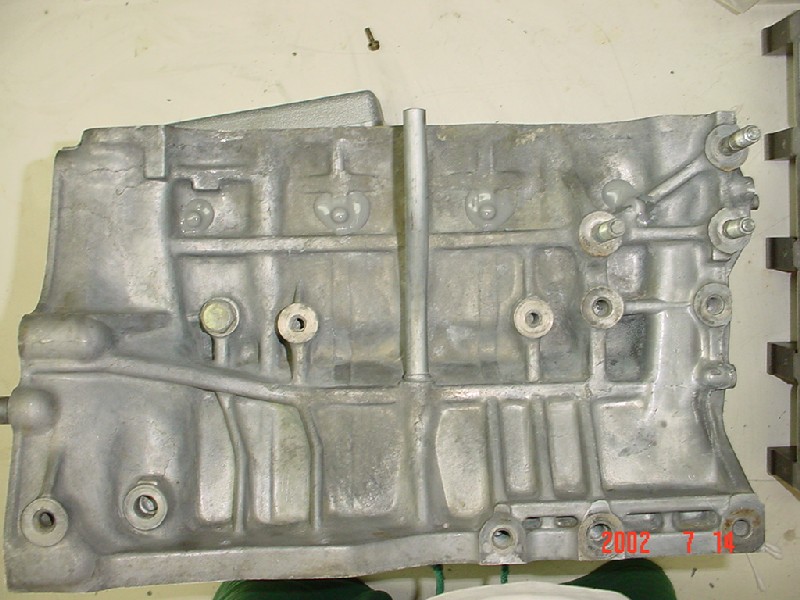

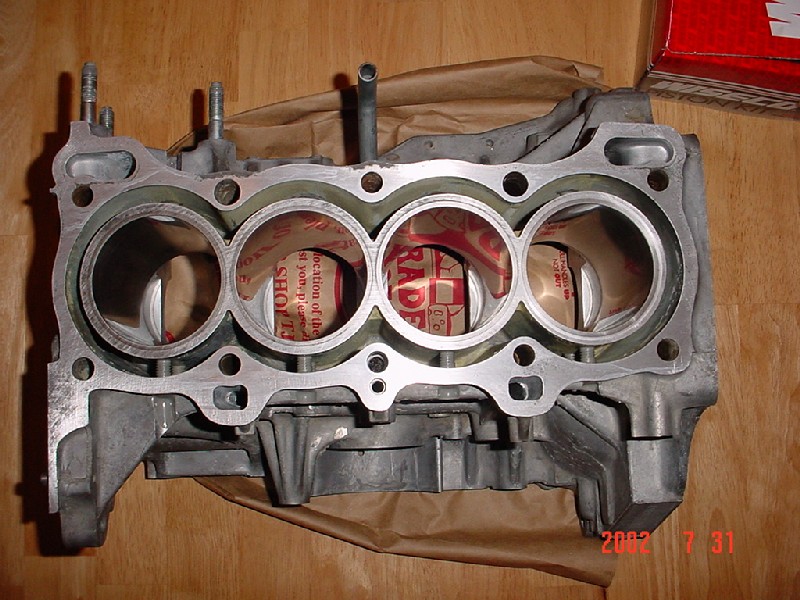

After the holes are drilled/tapped, the posts must be installed and sealed.

Finally, a bore/hone job is in order to make sure everything runs true. The stock sleeves are apparently accurate to .0001", so installing anything that touches them (posts or a blockguard) requires boring/honing to true everything up.