The JDM ZC cams drop right into this head. The JDM ZC is basically the japanese version of the 86-89 Integra engine. It makes ~135 hp vs 118hp for Integra. I was planning on using the ZC camshafts.

Here are the AEM adjustable cam gears. Since the head now sits about .035" closer to the block (due to decking/milling), the camshaft timing will be altered. Cam gears allow me to adjust for this in addition to being a valuable tuning tool. With the turbo installed, the ability to dial in/out overlap will be a valuable asset.

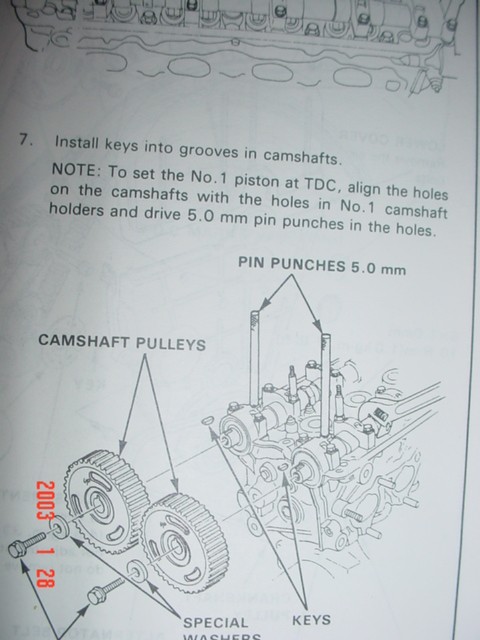

Here is the trusty Helms manual that illustrates that locking the cams at TDC using two 5mm punches is the way to line things up. 5mm punches are not easy to find, so I used two #9 drill bits. The shank measured 5.003mm. Perfect!

As you can see, something is seriously outta whack here. These are the ZC cams installed with the AEM gears. The Helms manual says that when the cams are locked at TDC via the 5mm punches and the timing marks on the gears (at 9 o'clock and 3 o'clock) are lined up, everything is in the correct spot. However, in this position both cams are off by 9 degrees! Time to start swapping parts...

Here is the winning combination. These are the 89 Integra cams in the 89 Integra head using the 89 Integra cam gears. The cams are at TDC and the timing marks (at 9 o'clock and 3 o'clock) line up correctly.

Knowing that the gears and head were correct, I installed the ZC cams and hoped that they would line up. Unfortunately, they do not. I did some research on this and apparently Honda did things a little different with the ZC. Since I wanted to make sure that I could accurately measure everything, I decided not to use the ZC cams. Any loss in power due to using the Integra cams will be made up for via my boost controller.

Knowing that the stock Integra camshaft gears were correct, I decided to compare them to the AEM gears to make sure that the markings were correct. Side by side, everything looks right...

With all those teeth on the cam gears, a quick glance can be deceiving. So, I looked closer and counted teeth. The AEM cam gears are marked wrong!

Unfortunately, AEM is the only company that "makes" cam gears for the 86-89

Integra, so I don't really have the option of returning these gears and

getting another brand (I wish I did). I chose to just make marks on the cam

gears that showed the correct location of the timing marks.

Unfortunately, AEM is the only company that "makes" cam gears for the 86-89

Integra, so I don't really have the option of returning these gears and

getting another brand (I wish I did). I chose to just make marks on the cam

gears that showed the correct location of the timing marks.

Since the camshafts are a long way from the oil pump and will be rotated several times during the process of tensioning the timing belt and adjusting the valves, plenty of assembly lube was used on the rocker arm pads, camshaft lobes, and cam bearing journals.

Here we are after everything has been aligned correctly.

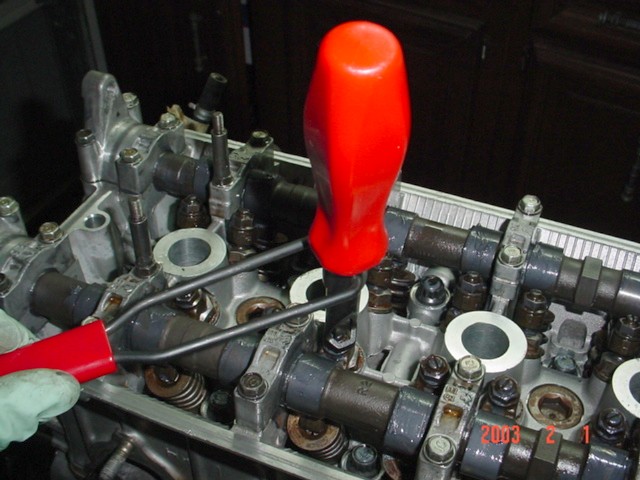

Before buttoning things up, a valve adjustment had to be done. This is the Snap-On tool. It's basically a wrench and a screwdriver in one. Valve adjustment is accomplished by turning a screw that increases/decreases the distance from the rocker arm pad to the camshaft lobe. The bolt is then secured via a jam nut. This tool makes it possible to hold the screw while tightening the nut. The same can be accomplished with a 12mm wrench and screwdriver, the but adjustment tool makes the job much easier.

It's almost done! This is how she sits until next time...